Supply Chains are the beating heart of the world’s economy. When that heartbeat faltered at the start of the Covid pandemic two things happened: consumers became acutely aware of the importance of supply chains, and a new agenda appeared around supply chain innovation to create more agile and resilient supply chain systems.

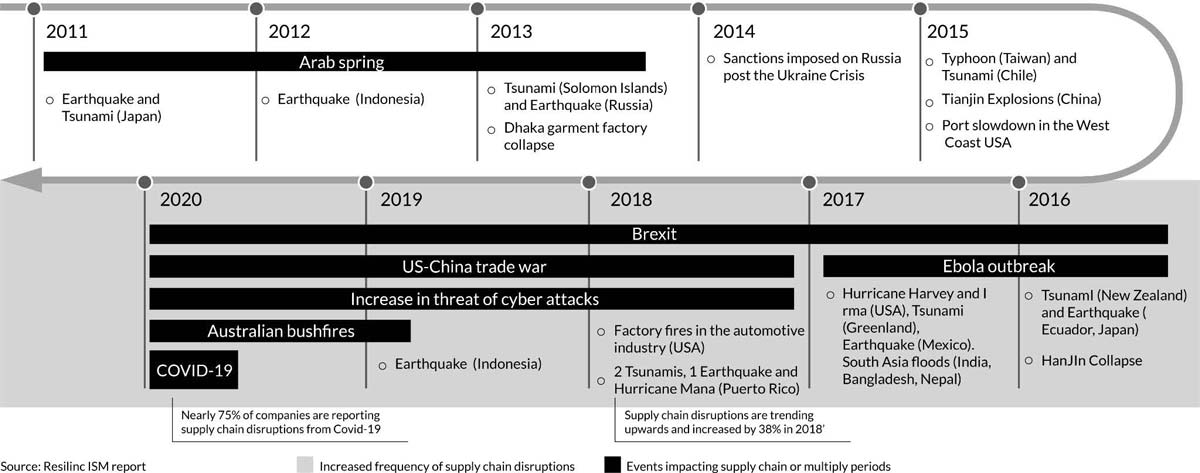

The pandemic sharpened the understanding that supply chain industry leaders and global corporations already had, to varying degrees: supply chain disruption that has been growing in frequency and magnitude for 10+ years is not going away.

And according to Bain & Company’s Expert Partner Gerry Mattios, speaking at the global Sigfox Connect conference in Nov 2020. “Industry leaders are prioritising risk mitigation as much as cost reduction. Increasing resilience is almost three times as important a priority for supply chain leaders in the next three years, compared to the last three years.”

Don’t Predict: Plan

You can’t predict an oil crisis, you can’t predict a war, you can’t predict another pandemic, and you can’t really predict a security hack. All you know is that any one of these, or any number of other challenges, is at some point likely to happen. Supply chain managers can, though, focus on what they can control, rather than on what they can’t predict.

As we navigate our way towards the post Covid era, we need to consider what supply chain organisations can do differently to manage crises and build resilience for the future.

1. Build in Redundancy to Your ERP System

Cyber attacks on supply chains are on the rise. According to Symantec’s latest Internet Security Threat Report, attacks on supply chain have increased by 78%, and ERP systems are a prime target.

Mitigating ERP cyber attacks has become a major board issue as executives now understand where that sits on the risk register. Hint: it’s ‘catastrophic impact’ and ‘likely’ to occur.

What happens when you can’t access the ERP system that is the lifeblood of your business? Your business stops.

To help mitigate this risk, supply chain leaders need to be working closely with IT security and risk management leaders to develop joint cybersecurity risk management approaches to their business and consider alternate solutions that do not rely totally on core IT/ERP systems for critical data transfer.

What if you had a separate system to tell you where your assets are? A system independent from your traditional transactional core systems. Then you have a way to control, mitigate and compartmentalise-risk.

Boards around the world are talking more about mitigating the impacts of cyber attacks on supply chains particularly sensitive to DDoS attacks (in which the network is overwhelmed with so many messages that it shuts down) on ERP systems. We see accelerating adoption around the world of IoT solutions that allow supply chain operations to deploy asset tracking and condition monitoring solutions offering independent access to essential information via the public, secure and global 0G Network.

If your ERP system gets hacked, you’d see value in knowing where all your shipments , containers or assets are across your national and global supply chain, literally 24/7 without any manual reporting.

It’s one way to build in much needed redundancy.

2. Improve Connected Visibility Now

Knowing where your assets are is a very quick way of mitigating risk.

What could supply chain leaders have done differently this year, had they known more about their supply chain assets location and condition?

Investing in secure, effective tracking technologies is imperative because it means identifying risks and stopping them in their tracks.

It means faster reaction times when things go wrong. It means you can rapidly identify disruptive demand and supply situations and secure alternate suppliers. Visibility builds resilience.

In many ways, this is the promise of IIoT. And it’s being realised by more and more global supply chain businesses around the world, especially through 0G technology.

Unfortunately, marketing around 5G has become so inflated that it is seen as a ‘silver bullet’. 5G has become a ‘catch all’ term that promises to deliver a long awaited utopian future of economic prosperity. But it’s not a silver bullet. Different technologies are fit for different purposes.

The technologies that have activated most large-scale IoT sensor networks for asset tracking in the supply chain, to date; are inexpensive non-cellular low-power wide-area (LPWA) technologies like LoRaWAN and Sigfox, not 4G LTE, and not 5G at all, yet. Sure, these technologies are coming, and they will compliment existing connectivity approaches and expand the market, but smart businesses won’t wait for that day.

While 5G is intended to bring faster speeds, Sigfox 0G technology is designed to serve distinct use cases where communication range must reach further, penetrate dense physical structures, and allow battery-operated infrequent communication devices to last in the field for extended periods of time.

While 5G may be optimal for video calls or smart goods in the home, the 0G Network is ideal for supply chain asset tracking, water, gas metering, agriculture, smart building, and smart park applications among others – IoT is already revolutionizing so many of these industries.

3. Reduce Human Error – Invest in Automation

Tracking and tracing assets is the first step in improving supply chain visibility and lifting resilience.

But as we explored earlier, a core system going down can compromise that data access.

If you can get your assets to tell you where they are, there’s less reliance on systems, and on humans running around gathering data.

In the case of Asia Pacific leading asset pooling company Loscam and their partner ACTIVE , finding lost assets scattered across Australia took “a massive amount of work”. They were manually tracking them down, even physically putting employees on planes to fly interstate and retrieve returnable packaging units that had been lost in transit. This was before they deployed a successful IoT asset tracking project.

Within four months of ACTIVE deploying Loscam’s end-to-end IoT-enabled solution operating long range, long battery-life 0G-enabled devices, it discovered 5% of units were incorrectly delivered to a competitor’s warehouse and 8% of units moved outside the customer’s logistics provider network. Although it is a common industry issue, seeing the actual data of the assets as they move between networks was a true light bulb moment.

The technology brought a much needed increase in visibility and control of assets, operational efficiency and asset utilisation. In one customer scenario, namely Mitsubishi Motors in Australia, it reduced the number of units needed by 30%, bottom line savings that were passed onto a delighted customer.

Track, Trace and Tell technology also improves efficiency through automating manual tasks. If nobody has to scan packages anymore, because the asset has become “smart” and can inform you of its location, human error is eliminated. There is less loss, less untraceable theft.

It’s all about enabling you to do less and get information with more accuracy, and faster.

In Europe, German-based DHL international courier parcel and express mail service deployed 250,000 logistics trackers in only six months to locate their postal roll cages. These insights mean that DHL can optimise asset utilisation and mitigate risks of shortfalls or bottlenecks due to unforeseen events or cyclical demand peaks.

When it comes to intercontinental shipping examples, Michelin transformed its tyre shipment efficiency with IoT -enabled containers across 170 countries. Other than gaining crucial transparency for better decision making across a complex supply chain to mitigate risks, other benefits include better route planning, less complex administration across many network partners and a much enhanced customer experience.

4. Screen Suppliers & Document High-value Data Flow

Supply chains are highly vulnerable due to the fact that they are, by nature, interconnected. Third-party suppliers can create something of a weakest link if not inspected properly for their commitment to security -an Opus and Ponemon Institute study showed that at least 59% of organisations have suffered from cyber attacks through third-party companies.

Competitive supply chains need a flexible system of suppliers and partners that offer the ability to swap input materials and components and rapidly introduce new products.

Dun & Bradstreet researchers found that 51,000 companies worldwide, 163 of which are in the Fortune 1000, had one or more direct or “Tier 1” suppliers in Wuhan, China, the city where the coronavirus hit first, while at least 5 million — 938 in the Fortune 1000 — had one or more “tier 2″ suppliers there.

There is no easy solution to ensuring end-to-end security, but organisations can start by defining their security requirements and thoroughly vetting each supplier before bringing them onboard as a regular partner.

A recent Gartner report on supply chain cyber security also encouraged supply chain leaders to research and document the flow of high-value supply chain data and information across systems outside core IT systems.

Ensuring regular communication and a strong cyber-risk management program can help companies gain a deeper understanding of suppliers and enable stronger collaboration.

Use the Lessons of 2020 to Plan for the Future

Creating a multifaceted supply chain strategy will cost money, but investing in strong risk management could save your company and your business. Those who use a crisis to make investments and accelerate change come out better off. Resilient supply chains not only recover from disruption, with the right level of investment, they can become a source of competitive advantage.

As the year comes to an end, it’s worth reflecting on what you could have done differently with greater visibility and data in 2020, and use those lessons to plan for next year.

Our future looks to hold just as much uncertainty and upheaval, but armed with the knowledge and insight from 2020, plus innovative technologies and strong board appetite for change, supply chain leaders can succeed in building greater resilience.

Loic Barancourt

Co-founder and CEO of Thinxtra, The IoT Telco

Sigfox 0G Network Operator in Australia, New Zealand and Hong Kong

About Thinxtra

Thinxtra, The IoT Telco, accelerates business efficiency by connecting assets and making them work smarter. We provide fit-for-purpose Internet of Things (IoT) connectivity and solutions that are economically viable and operationally scalable.Thinxtra owns and operates the Sigfox 0G Network in ANZ & HK and is a member of 0G United Nations, the global association of 0G Network Operators and is exclusive distributor of Soracom cellular IoT services.

Visit thinxtra.com for more information.