As technological innovation advances, it is common for prices to drop and products to improve and the Internet of Things (IoT) has followed this common global trend. For the supply chain and logistics industry, IoT solutions promise endless innovative applications that deliver operational efficiencies, create business opportunities and support competitive advantage. Yet, despite widespread IoT interest, debate and many trials, it is rare to find industrial IoT projects that have reliably scaled.

In our experience of working with many different organisations in this industry around the world, the biggest challenge for scaling occurs because most IoT trials and Proof of Concepts (PoCs) aim to only prove the technology’s capabilities. Most don’t seek to prove, validate or understand the business benefits that could be unlocked by the data insights IoT solutions can deliver. Many don’t explore deeply enough the operational requirements and cost impact when it comes to connecting hundreds of thousands, even millions of assets through attached battery-powered IoT devices.

The key for successful fit-for-purpose industrial IoT solutions at scale, in a national or global context, lies in the ability to translate the data into actions that ultimately realise the value, regardless of the technology choice.

Six Key Considerations

1. Technology Agnostic Approach

It might come as a surprise as we are talking about technology, and despite what many may claim, there is no single IoT technology, solution, or standard that can solve every business problem. In fact, the opposite claim is probably more accurate: the business requirements, operational and cost constraints will eventually lead to the right technology choices.

Every IoT technology brings different strengths and weaknesses. They only emerge when data requirements are mapped to specific operational needs, may they be at local or global scale.

The plethora of IoT solutions available in the market can be confusing and challenging to navigate. Successful industrial IoT projects are technology agnostic, and need to easily become a natural extension of day-to-day operations. This means the solution needs to be easy to implement and maintain, be robust, reliable and scalable wherever the business operates, regardless of the underlying technology.

2. Clarity of The Business Problem or Opportunity

Instead of seeking the latest bright new shiny technology to adopt, the best starting point for leaders is to ask what business problems IoT technology needs to solve and bring the right stakeholders together. Like any transformation project, the adoption of IoT solutions requires a holistic view to orchestrate changes across multiple functions in any organisation.

For example, if the customer experience needs to be improved to maintain competitiveness, or operational costs can be lowered, gathering accurate location or condition information of assets as they move through the network could enable these outcomes to be achieved.

If the objective is to support growing demand whilst minimising additional capex expenditure, increasing asset utilisation through data insights can enable the reduction of loss rates, remote asset visibility and therefore faster asset rotation.

Increasingly we see innovative IoT solutions not only solving known problems with generating the necessary data. More and more we see new disruptive business models entering markets that are led by principles of traceability, usage based pricing models and principles of the circular economy.

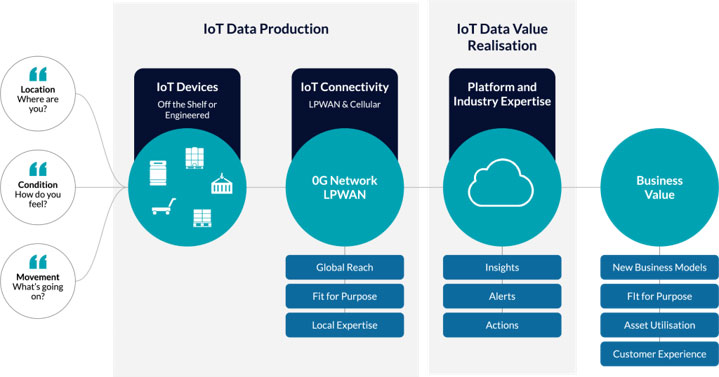

3. Ultimately it is all about Data: Requirements and Value

IoT is more about data than the name suggests. Data from connected devices help run and optimise a business by enabling faster, better quality decision-making. Devices attached to the assets you monitor share updates on key tracking criteria, such as location, temperature or humidity, at regular or event-driven intervals. Imagine your asset “could tell you” when it is staying for more than the contracted 60 days in a clients warehouse, or sends an alert when it leaves a defined area.

Data produced from devices can trigger automated workflows or alert stakeholders to take action, faster and more efficiently than through traditional, manual information flow. For example, if a device monitoring temperature inside a truck transporting chilled goods between cities indicates the temperature is rising above approved levels, an automated alert notifies the Logistics Manager, or truck driver, of the problem. Corrective action occurs based on data produced in real-time.

Once the data requirements, production methods, processing and management costs are defined, the project team can focus on designing the best fit-for-purpose solution, across devices, data, connectivity, digital platforms, process flows and operational support.

4. Fit-for-purpose Solution Requirement List

Although many business environments may seem similar, no two businesses are identical in their business offering or operational practices.

These differences mean it is rare to deploy an IoT solution out-of-the-box without the need for some customisation. For example, IoT devices must be attached to physical assets in a way that won’t hinder existing operations.

The logistical cost of attaching thousands of devices onto assets also means the device must be durable, quick to install, and able to withstand different weather, temperatures, humidity and vibration, all the way down to the choices of the right screws, material or brackets.

Similarly, the length and predictability of the IoT Device battery life has a very significant impact on ROI as it impacts the Total Cost of Ownership (TCO) of maintaining the IoT solutions once it has deployed.

Ideally, it supports the lifetime of the asset, which can be many years, and delivers a set-and-forget deployment. Every business has different asset types, from wooden crates, beer kegs, shopping trolleys, baggage trolleys, vehicles, and even livestock. Considering all these variables means that you are served best by a fit-for-purpose solution that is configurable and flexible with minimum changes to be made.

5. Total Cost of Ownership (TCO)

The Total Cost of Ownership (TCO) of an IoT initiative is a key decision factor for every organisation and must include the operational BAU impact and required changes across the business.

A holistic approach is needed to consider all cost drivers for the IoT project deployment, and on an ongoing basis. Critical to include in TCO calculations are costs of:

- purchase, or design and development of the right IoT devices to produce and communicate the required data.

- quality, reliability and life of the battery to run the IoT device.

- installation, deployment and maintenance costs.

- customisation for efficient operation.

- reliable communications of the data.

- the digital platform enabling workflows that use the data to create operational efficiencies.

- change management to nurture and sustain adoption.

Successful IoT solutions create significant business value to justify the investment costs of transformation and beyond.

6. The Business Case – Small Data

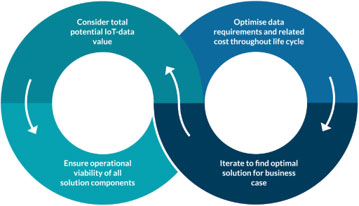

To find the right business case formula it requires an iterative process to reach the right balance between the key ROI inputs:

- Value of Data

- Operational Feasibility

- Total Cost of Data Production

To design a solution that is financially viable and operationally scalable calls for a close examination of an asset’s operational and data requirements, throughout its lifecycle, alongside a comparative analysis of data production cost. From there we discover possible viable solutions and then adjust data production requirements, based on the data value proposition, to find the best fit-for-purpose solution that delivers optimal business benefit.

Sam Sharief

COO and co-founder of Thinxtra, The IoT Telco

Sigfox 0G Network Operator in Australia, New Zealand and Hong Kong

About Thinxtra

Thinxtra, The IoT Telco, accelerates business efficiency by connecting assets and making them work smarter. We provide fit-for-purpose Internet of Things (IoT) connectivity and solutions that are economically viable and operationally scalable.Thinxtra owns and operates the Sigfox 0G Network in ANZ & HK and is a member of 0G United Nations, the global association of 0G Network Operators and is exclusive distributor of Soracom cellular IoT services. Visit thinxtra.com for more information.